The Advantages Of A Planetary Gear Reducer

1. High Transmission Ratio:

Planetary gear reducers can achieve high transmission ratios, typically reaching dozens or even hundreds of times.

This makes them very useful when a significant reduction in rotational speed and an increase in torque output are needed.

2. High Torque Output:

Planetary gear reducers increase torque output through the rotation of multiple gears.

Their structural design distributes the load across each gear, thereby enhancing the overall torque transmission capability.

3. Multi-Stage Transmission Capability:

Planetary gear reducers can further reduce rotational speed and increase torque output by linking multiple reduction stages in series.

This multi-stage transmission structure offers higher efficiency and a greater torque transmission ratio.

4. Compact Design:

The design of planetary gear reducers is compact and simple in structure.

They typically have a small volume and weight, making them suitable for applications with limited installation space or where lightweight is required.

5. Smooth Output:

Due to the load distribution among multiple gears, the output speed of planetary gear reducers is more stable, reducing vibration and impact, thereby improving the system’s smoothness.

In summary, planetary gear reducers possess the advantages of high transmission ratio, high torque output, multi-stage transmission capability, compact design, and smooth output, making them widely used in many mechanical transmission systems.

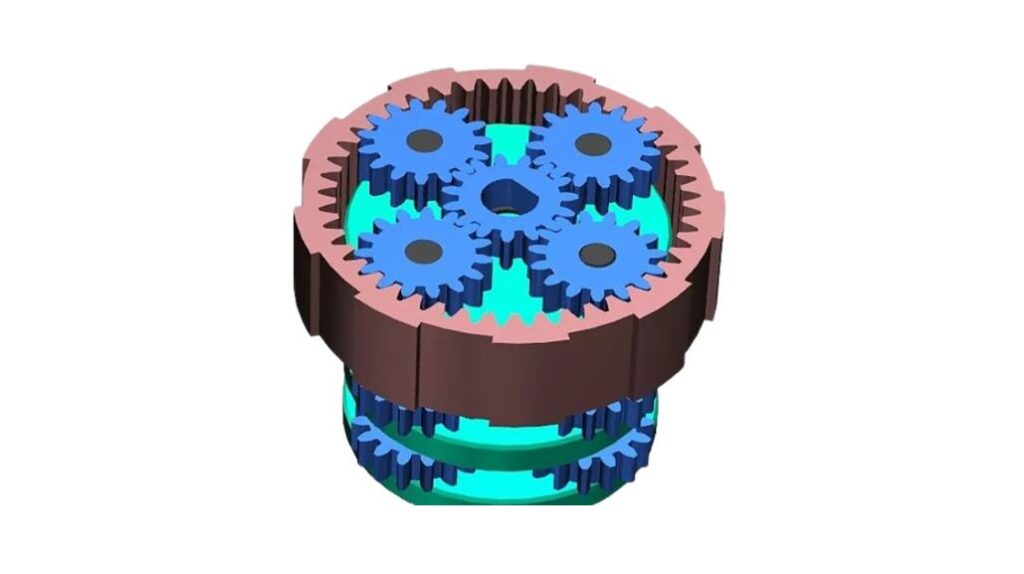

Main Components Of A Planetary Gearbox

A planetary gearbox is a mechanical device commonly used for transmitting power and converting rotational speed. It consists of several main components, including:

- Sun Gear: The sun gear is the central gear of the planetary gearbox. It drives the entire gear system by receiving input power.

- Planet Gears: The planet gears revolve around the sun gear. There are usually two or more planet gears, and they are connected by the planet carrier.

- Planet Carrier: The planet carrier is the support structure for the planet gears, connecting them together and allowing them to rotate around the sun gear.

- Ring Gear: The ring gear is the outer gear of the planetary gearbox. It rotates simultaneously with the planet gears and transmits the output force and torque to an external device.

In a planetary gearbox, the sun gear acts as the input shaft, and the ring gear serves as the output shaft. When the sun gear rotates, the planet gears revolve around it via the planet carrier, while the ring gear remains stationary. This design allows for various speed and torque transformations, providing different transmission ratios.

It is worth noting that planetary gearboxes may also include other auxiliary components such as bearings, seals, and lubrication systems to ensure proper operation and reduce friction loss. While different planetary gearbox designs may vary slightly, the above components are the basic elements of their construction.

Thank you for reading. Looking forward to serving you with our exceptional gear solutions. #BeyondGears

Read More: