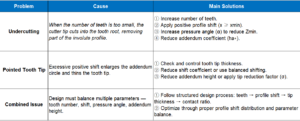

Avoid These Two Hidden Traps in Gear Design: Undercutting and Pointed Tooth Tips

How to Avoid Undercutting and Pointed Tooth Tips in Gear Design 1. Understanding the Root Causes Before solving the problem, it’s crucial to understand why

How to Avoid Undercutting and Pointed Tooth Tips in Gear Design 1. Understanding the Root Causes Before solving the problem, it’s crucial to understand why

How precision in every stage — design, manufacturing, assembly, and maintenance — defines the reliability and performance of gear systems. 1. What Is Gear Transmission

Shot peening is a cold working process where a stream of high-speed shots bombards the metal surface, introducing residual compressive stress into the surface layer.

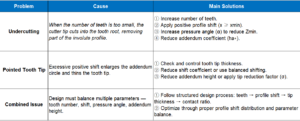

In precision engineering, gears are fundamental elements of power transmission systems. To ensure smooth operation, durability, and efficiency, it is essential to evaluate gear accuracy

Improving gear transmission accuracy is not a single-step improvement but a comprehensive engineering process. It requires precise control across the entire chain, from design, materials,

When designing or analyzing gear systems, two fundamental terms often arise—reference circle and pitch circle. While they are sometimes used interchangeably, especially in casual contexts,

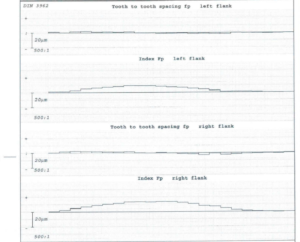

In the world of mechanical engineering and robotics, gear reducers—also known as speed reducers—play a vital role in optimizing motion control. These components are essential

Low-speed, heavy-duty gearboxes are essential in industrial applications where high torque and low rotational speed are required. Their design must balance high load capacity, fatigue

High-speed gear transmission design is one of the most challenging areas in mechanical power transmission. Its core lies in balancing dynamic behavior, thermodynamic effects, and

Sourcing custom gears from China can significantly reduce costs while ensuring high product quality. With a well-developed gear manufacturing supply chain, China offers professional services

Today, let’s look at some common metallographic structures in steel, including ferrite, cementite, pearlite, austenite, martensite, bainite, ledeburite, and Widmanstätten structure, and compare their mechanical

When it comes to gear design and transmission performance, one important concept that cannot be overlooked is the contact ratio, often denoted by the Greek

We are ready, Let’s talk today.