Principles of Gear Grinding Stock Allowance Determination

In gear tooth grinding processes, controlling the amount of material to be removed, known as the stock allowance, is a crucial aspect. The stock allowance

In gear tooth grinding processes, controlling the amount of material to be removed, known as the stock allowance, is a crucial aspect. The stock allowance

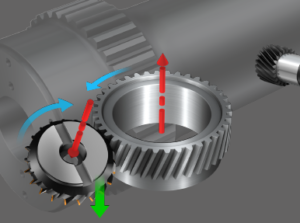

Spiral bevel gears, also known as helical bevel gears, play an indispensable role in the field of automotive drivetrains due to their smooth transmission. The

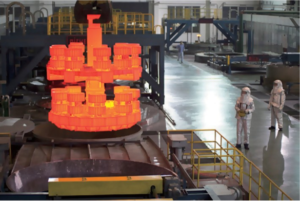

Quenching What is quenching? Quenching of steel refers to a heat treatment process where the steel is heated to the critical temperature above Ac3 (for

What is Power Skiving? Power skiving is a continuous cutting process that can complete all processing steps in one clamping. It essentially combines the two

Gear shaping principle Gear shaping is a tooth surface processing method that uses a gear shaping cutter to process internal and external gears or racks

The reducer is widely used in industrial production. The gear transmission of its main component has a strict transmission ratio. The processing accuracy of the

Introduction: As a crucial component in automobiles, the automotive gears are primarily utilized for power transmission and motion, altering speed ratios between the engine’s crankshaft and

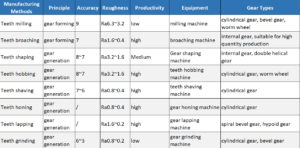

Gears are essential components in various mechanical devices that transmit power from rotary to linear motion. The right gear manufacturing process is necessary to ensure

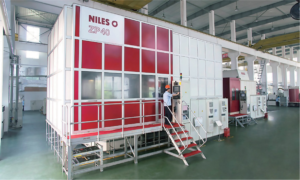

ID grinding is typically used for parts that have high accuracy demand of internal features.

We are ready, Let’s talk today.