Understanding Key Indicators in Gear Accuracy Inspection

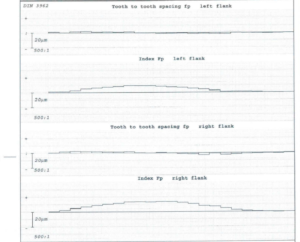

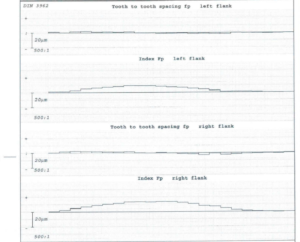

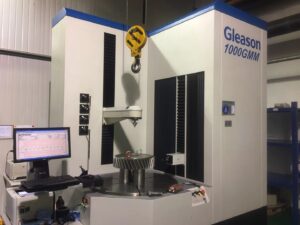

In precision engineering, gears are fundamental elements of power transmission systems. To ensure smooth operation, durability, and efficiency, it is essential to evaluate gear accuracy

In precision engineering, gears are fundamental elements of power transmission systems. To ensure smooth operation, durability, and efficiency, it is essential to evaluate gear accuracy

The tip diameter of a gear with an odd number of teeth cannot be measured directly. This is because, in such gears, the tooth opposite

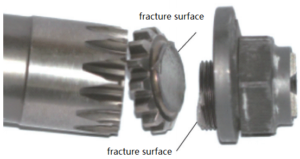

Gear failures occur due to complex working conditions and exhibit different characteristics under different operating conditions. During operation, gears experience bending stress at the tooth

Gears that are accurately manufactured and tested can help ensure that machines operate efficiently, reliably, and safely.

Properly testing the accuracy of gears is essential to identify any potential defects or inaccuracies,so that we can ensure they meet the levels of quality and performance.

We are ready, Let’s talk today.