A Brief Introduction To The Module Of Gears

Gear module is one of the essential parameters in gear design and manufacturing in the field of mechanical engineering. It not only affects the geometric

Gear module is one of the essential parameters in gear design and manufacturing in the field of mechanical engineering. It not only affects the geometric

The selection of gear teeth involves various engineering considerations, typically determined based on the following main factors: Power Transmission and Torque: The number of gear

Enhancing Gear Performance: Gears serve as the backbone of countless mechanical systems, from heavy machinery to everyday appliances. Keeping them in optimal condition requires diligent

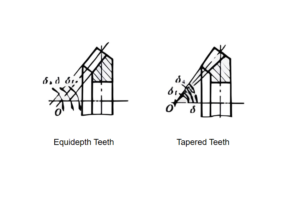

In the intricate landscape of gear manufacturing, the selection between equi-depth teeth and tapered teeth carries profound implications, with each presenting distinct advantages and characteristics.

What is a shaft? A shaft is essentially a rotating component of any machine, typically having a circular cross-section, used to transmit power from one

The analysis of gearbox noise is an important topic in the field of mechanical engineering, involving the identification, measurement, and analysis of various sounds generated

There are many factors that affect gear mesh accuracy, and these factors can have an impact on the meshing state and operational performance of gears.

The concept of gears has been in existence for a very long time, as they are among the oldest mechanical components known today. Whether in

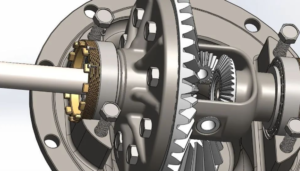

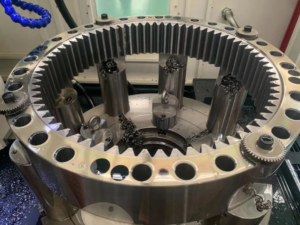

The planetary gear reducer is a highly utilized device in the transmission system. In industrial and mechanical applications, the presence of planetary gear reducers is

Working Principle of Reducer 1.1 Operation Mode of ”Earth Rolling“ A reducer is a device where a high-speed input drives an output shaft. It is

The gear industry is the foundation of the mechanical sector, and compared to the mechanical equipment industry, the gear industry is the most technologically and

Gear oil mainly refers to the lubricating oil used in transmissions and rear axles. It differs from engine oil in terms of usage conditions, composition,

We are ready, Let’s talk today.